Accessories for i3D

Testing tips and consumables:

#1 i3D consumables

Indenter type A

High-precision indenter (diamond) for performing indentation testing according to DIN SPEC 4864.

#2 i3D consumables

Indenter type B

High-precision indenter (diamond) for performing indentation testing according to DIN SPEC 4864.

#3 i3D consumables

Indenter type C

High-precision indenter (diamond) for performing indentation testing according to DIN SPEC 4864.

#4 i3D consumables

Strength plate (soft)

Strength plate for the calibration of i3D devices, with a medium strength range of approximately 200 to 300 MPa.

#5 i3D consumables

Strength plate (middle)

Strength plate for the calibration of i3D devices, with a medium strength range of approximately 500 to 700 MPa.

#6 i3D consumables

Strength plate (hard)

Strength plate for the calibration of i3D devices, with a medium strength range of approximately 1100 to 1200 MPa.

Hardness Reference Plates

Hardness reference plates are an essential tool for the regular and precise verification of your hardness testing devices. According to international standards DIN EN ISO 6506 (Brinell), DIN EN ISO 6507 (Vickers), DIN EN ISO 6508 (Rockwell), and DIN EN ISO 4545 (Knoop), periodic tests with calibrated and certified hardness reference plates must be conducted and documented to ensure the accuracy of hardness testing.When buying hardness reference plates online, you should look for the highest quality and reliable calibration. Our hardness reference plates provide minimal hardness deviation and are calibrated according to UKAS standards, ensuring your test results remain precise and compliant with standards.

The use of hardness reference plates is particularly important to avoid systematic measurement deviations. Re-testing is necessary after any changes to machine settings, such as switching test methods or indenters. Additionally, daily verification with at least one or two test impressions per hardness scale is required and is frequently reviewed during audits.

With our range of hardness reference plates, ordering the right solution for your application is simple. We offer plates for all standard hardness testing methods, including Vickers, Rockwell, Knoop, and Brinell, and supply industries worldwide, such as aerospace, automotive, mechanical engineering, and medical technology.

Ensure the accuracy and reliability of your hardness testing devices and order high-quality hardness reference plates online with us today!

Hardness Reference Plates for Calibration of Hardness Testing Devices

Selection of plates for Rockwell HRC:

#9 Hardness comparison block

Rockwell 25 HRC

Rockwell 25 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#10 Hardness comparison block

Rockwell 30 HRC

Rockwell 30 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#11 Hardness comparison block

Rockwell 35 HRC

Rockwell 35 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#12 Hardness comparison block

Rockwell 40 HRC

Rockwell 40 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#13 Hardness comparison block

Rockwell 45 HRC

Rockwell 45 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#14 Hardness comparison block

Rockwell 50 HRC

Rockwell 50 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#15 Hardness comparison block

Rockwell 55 HRC

Rockwell 55 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#16 Hardness comparison block

Rockwell 60 HRC

Rockwell 60 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#17 Hardness comparison block

Rockwell 65 HRC

Rockwell 65 HRC, according to DIN EN ISO 6508 with DAkkS calibration certificate.

#18 Hardness comparison block

Vickers 110 HV1

Vickers 110 HV1, according to DIN EN ISO 6507 with DAkkS calibration certificate.

#19 Hardness comparison block

Vickers 110 HV2

Vickers 110 HV2, according to DIN EN ISO 6507 with DAkkS calibration certificate.

#21 Hardness comparison block

Vickers 110 HV10

Vickers 110 HV10, according to DIN EN ISO 6507 with DAkkS calibration certificate.

#22 Hardness comparison block

Vickers 110 HV30

Vickers 110 HV30, according to DIN EN ISO 6507 with DAkkS calibration certificate.

#25 Hardness comparison block

Brinell 110 HBW1/10

Brinell 110 HBW1/10, according to DIN EN ISO 6506 with DAkkS calibration certificate.

#26 Hardness comparison block

Brinell 110 HBW1/30

Brinell 110 HBW1/30, according to DIN EN ISO 6506 with DAkkS calibration certificate.

#27 Hardness comparison block

Brinell 110 HBW1/5

Brinell 110 HBW1/5, according to DIN EN ISO 6506 with DAkkS calibration certificate.

#28 Hardness comparison block

Brinell 110 HBW10/1000

Brinell 110 HBW10/1000, according to DIN EN ISO 6506 with DAkkS calibration certificate.

#29 Hardness comparison block

Brinell 110 HBW10/3000

Brinell 110 HBW10/3000, according to DIN EN ISO 6506 with DAkkS calibration certificate.

Mechanical Material Testing

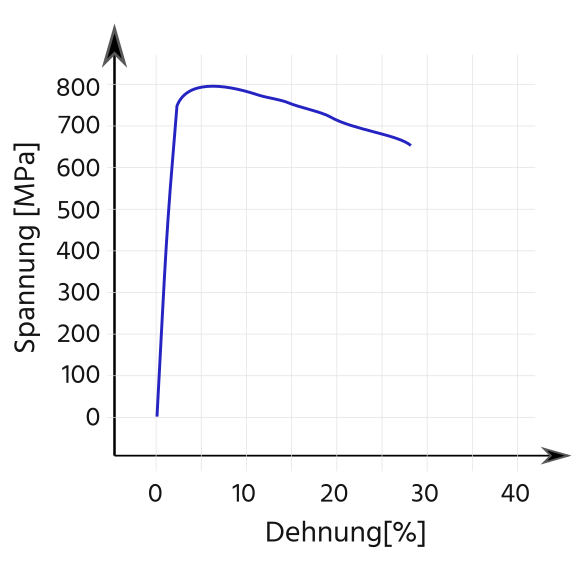

#7 Material Testing

Indentation Plastometry Imprint Test

The indentation plastometry based imprint test according to DIN SPEC 4864 enables the precise determination of yield strength, tensile strength, and ductility from indentation tests and serves as an effective alternative to tensile testing. It is used for small parts, welds, and cold working, providing valuable data for finite element analysis (FEM).

#8 Material Testing

Micro Tensile Test

The microtensile test is used for the mechanical characterization of materials at the micro level. The key criterion for using microtensile tests is the need to examine small test volumes, ranging from a few millimeters down to micrometers. With the increasing miniaturization of mechanically stressed systems, understanding deformation and strength behavior in this scale range becomes crucially important.

#9 Material Testing

Vickers Hardness Test

The Vickers hardness test measures material hardness using a diamond pyramid indenter. It is commonly used in metalworking, tool manufacturing, and materials research, for example, for steel and ceramics.

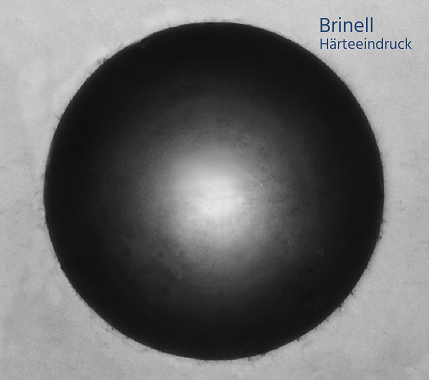

#10 Material Testing

Brinell Hardness Test

The Brinell hardness test assesses material hardness by pressing a steel ball under a defined pressure. It is commonly used in the metal industry, particularly for cast iron and steel alloys, to determine their strength.

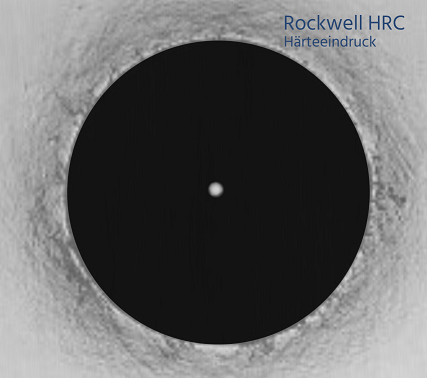

#11 Material Testing

Rockwell Hardness Test

The Rockwell hardness test (HRC) measures the hardness of materials by pressing a conical diamond into the surface. It is commonly used in manufacturing and quality assurance, for example, to quickly determine the hardness of metals and plastics.

#12 Material Testing

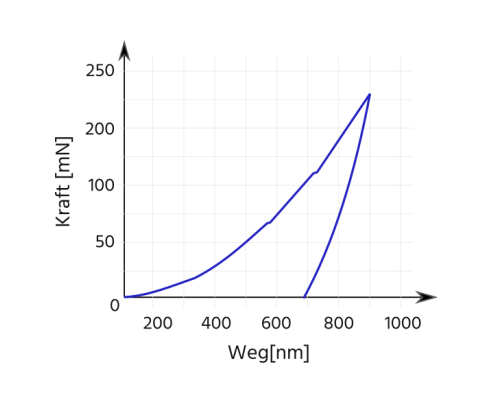

Instrumented Indentation

Instrumented indentation testing is a method used to analyze the mechanical properties of materials, particularly in materials research and testing. This testing technique allows for precise evaluation of the force-displacement curve and is used to characterize hardness, elastic properties, as well as derive insights into material strengths.

Optical 3D-Measurement

#1 Optical 3D Measurement

Roughness Measurement

The roughness measurement (surface measurement) is used to determine the surface roughness. For this purpose, a two- or three-dimensional profile of the surface is measured. From this, various roughness parameters are calculated using standardized methods to characterize the surface roughness.

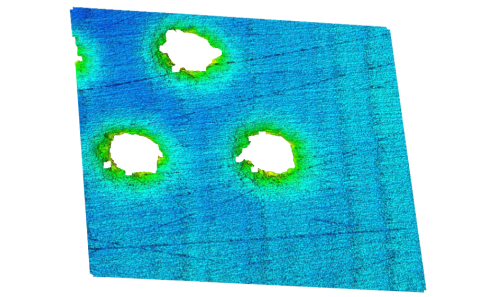

#2 Optical 3D Measurement

Topography Measurements

Capturing surface profiles and structures to create three-dimensional height maps of surfaces. This is crucial for the evaluation of materials such as semiconductors, microchips, and other finely structured components.

#3 Optical 3D Measurement

Flatness Inspection

Flatness testing is a critical process for determining the flatness of surfaces, especially important in the semiconductor industry and the manufacturing of optical components such as lenses and mirrors. Through precise measurement methods, flatness testing enables the identification of irregularities, ensuring the quality and functionality of the products.

#4 Optical 3D Measurement

Abrasion Studies

Wear and abrasion studies are essential procedures for assessing wear on surfaces and materials, caused either by specific tests or long-term use. These analyses are crucial for evaluating the durability and quality of materials or coatings and identifying potential weaknesses.

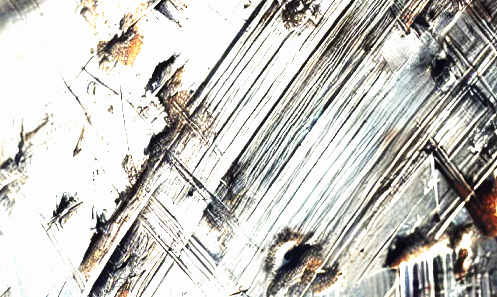

#5 Optical 3D Measurement

Defect and Failure Analysis

Defect and failure analysis plays a central role in detecting and characterizing microcracks, scratches, particles, or other defects on surfaces that can significantly affect the performance and quality of products. Accurate identification of these flaws is crucial for quality assurance and allows companies to implement targeted corrective actions.