Yield strength and tensile strength from indentation.

By using the indentation plastometry phenomena the Imprint Test method opens up the possibility of testing the yield strength and tensile strength - without a tensile test. The approach describes the evaluation of the pile-up, captured by optical 3D measurement, of an indentation and using FEM calculations. In essence, the pile-up of the material behaves characteristically according to its mechanical properties, so the evaluation of the pile-up enables the determination of the plastic flow curve.The following examples give you an insight into new testing possibilities

- Weld seam examination

- Characterize degrees of forming

- Small parts

- Multisample screening

- Case hardening depth

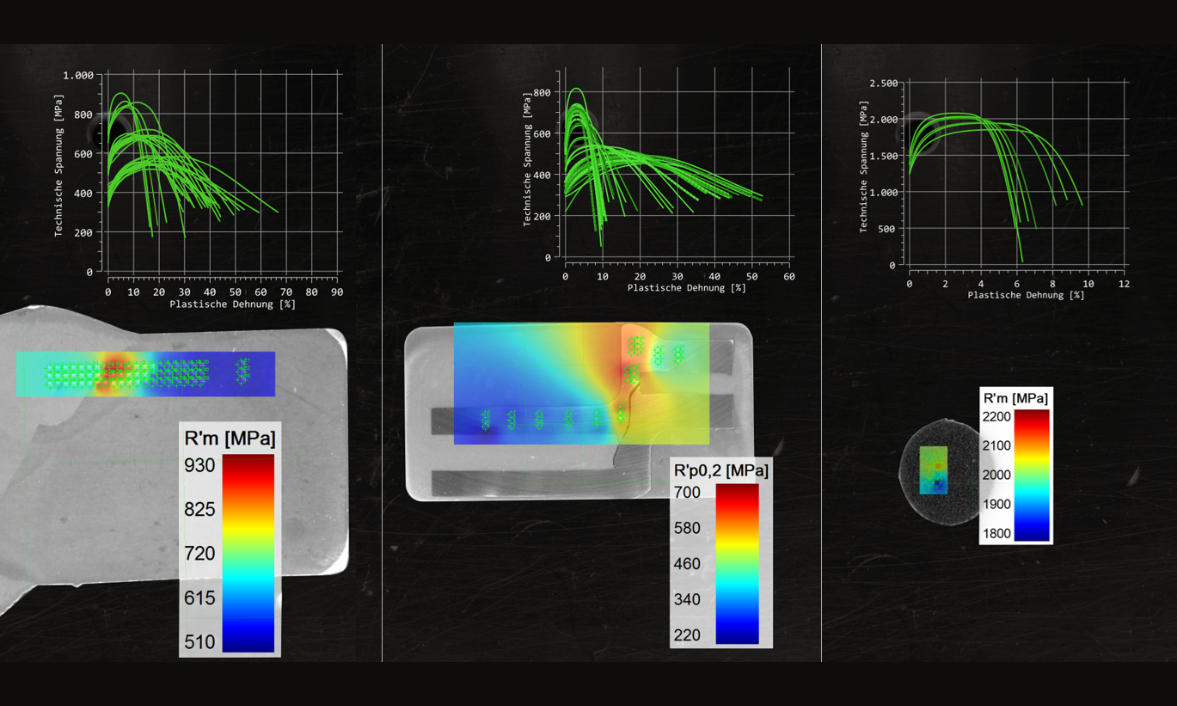

Weld seam examination. Testing of tensile strength, yield strength and ductility.

In the context of research work, weld joints were characterized for their mechanical properties in the base material, transition zone, heat-affected zone, and weld seam. Traditionally, the Vickers hardness test was used to measure local hardnesses with measurement points arranged in lines along the weld joint. The Imprint Test according to DIN SPEC 4864 determines:- The comparative tensile strength RIm,

- Comparative yield strength RIp0.2,

- Strain hardening exponent n,

- Ductility D.

These values describe the mechanical properties of the weld joint better than simple hardness values and help optimize the welding process.

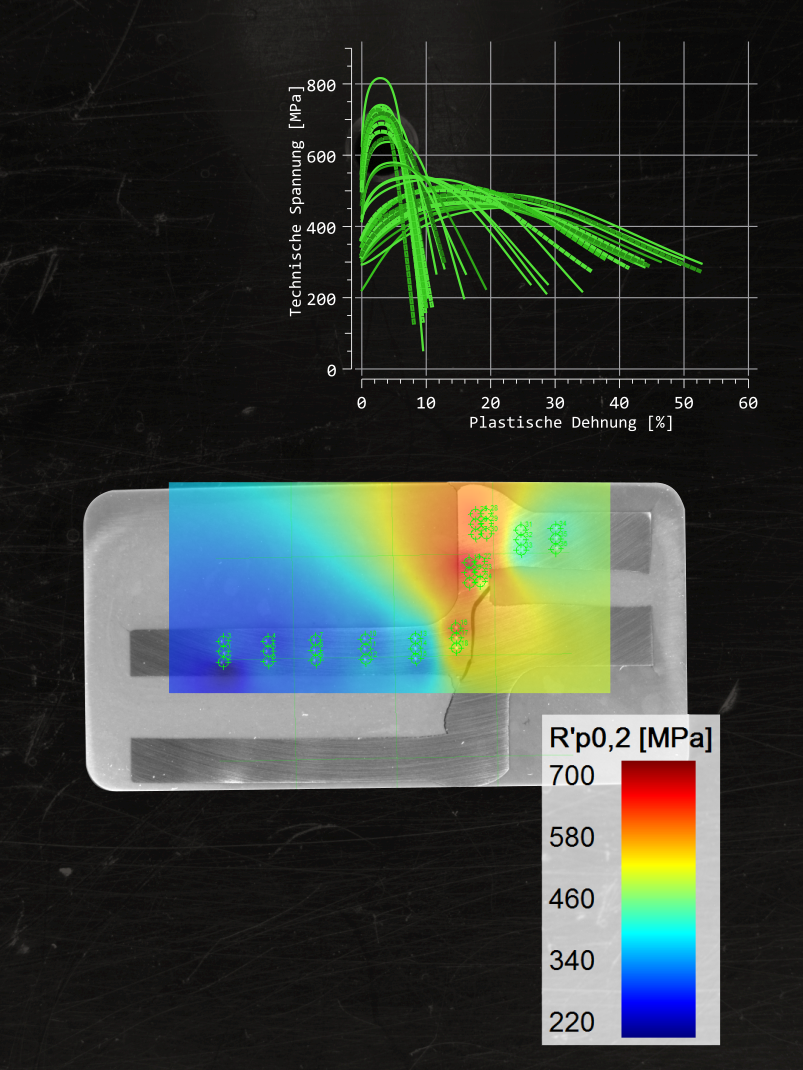

Traceability of plastic deformation.

In this case, a component was heavily deformed by stress, even resulting in a crack. While indenting a grid-like arrangement of measurement points along the part, the corresponding zones could be identified. This also provided a precise insight into the local mechanical properties.

Small parts - test where it matters.

Safety-relevant parts can often be small. Zones within a few millimeters often play a significant role. Traditionally, hardness testing is often used for mechanical characterization in this context. Development departments and engineers often need mechanical properties, such as yield strength and tensile strength, to make accurate statements about the strength of constructions. Measurement points with a diameter of about 120 µm were set here to characterize the strength gradient from the edge to the core more comprehensively using the Imprint Method.

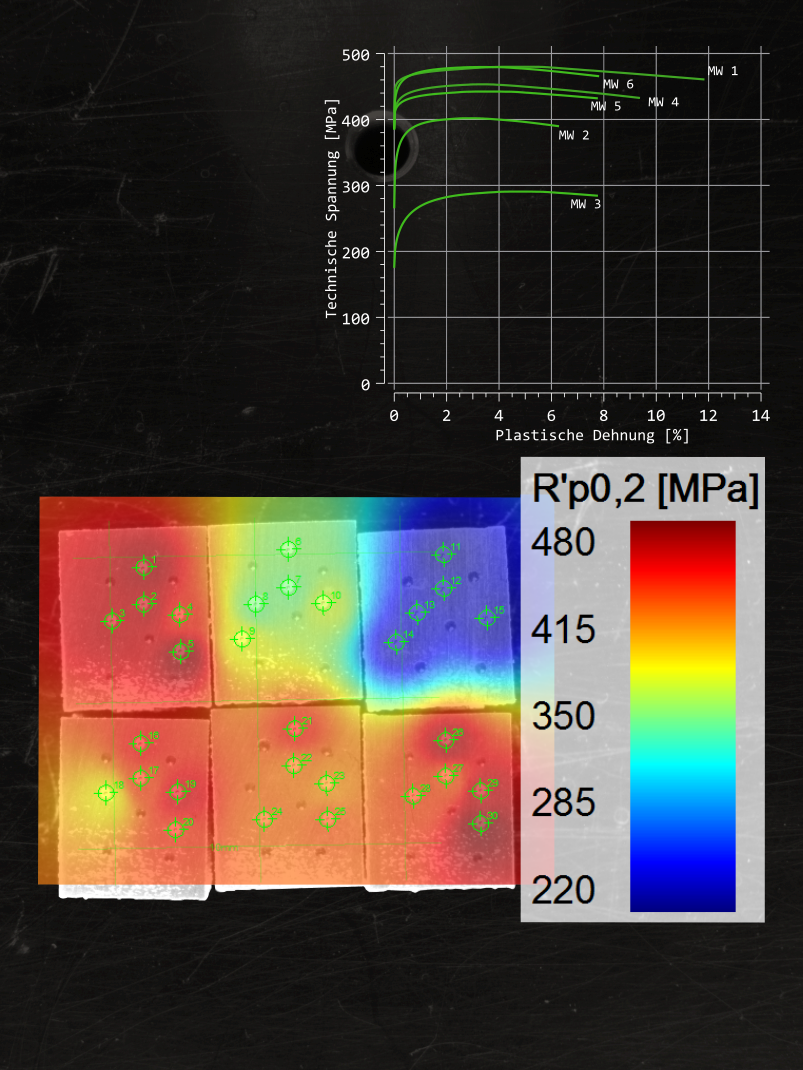

Multisample screening | High trough output testing - supporting alloy development with fast available data.

In the early stages of alloy development, quickly accessible data, including mechanical properties, is often very helpful. It accelerates the process of development through close iteration loops, where steps between adjusting parameters and getting data are accelerated exponentially. Within approx. 30 minutes, 30 plastic flow curves were measured here. These clearly show the differences in strength.

Hardening gradient.

Semifinished products as solid materials can often exhibit edge-core differences in the cross-section, especially if work hardening processes have been applied. It can be very helpful to know these local differences and not just rely on the supplied certificates. If, for example, an ablative machining process follows of such a material, the overall strength of the material decreases accordingly. Knowing the differences in strength provides safety.