Indentation Plastometry - i3D®

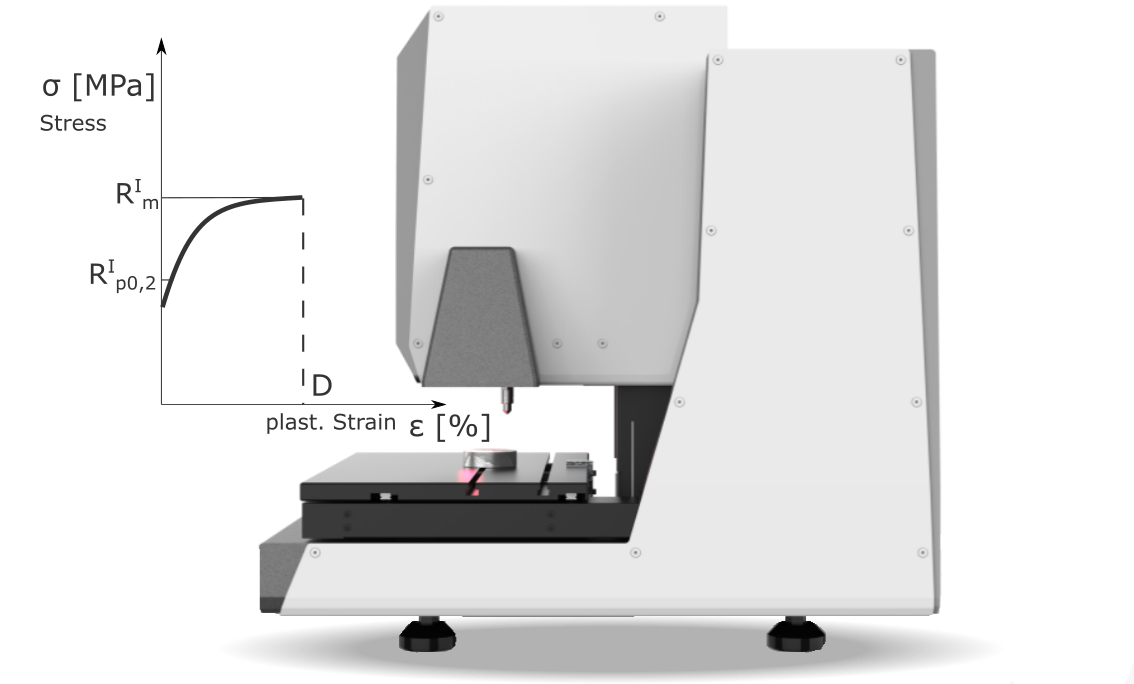

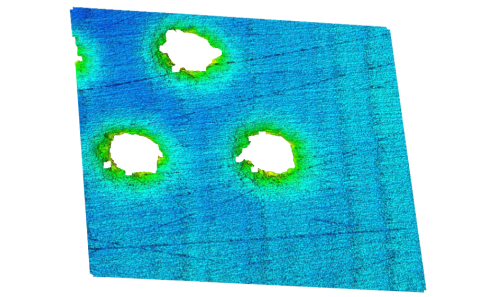

The principal of indentation plastometry according to the Imprint Test is a powerful solution for material testing. It allows the characterization of mechanical properties directly from indentation. This technology simplifies everyday processes and enables mechanical testing, which is not feasible with conventional methods. High-performance determination of yield strength (YS), tensile strength (UTS) and ductility.The testing times are impressively short – only about 45 seconds per stress-strain curve, and that requires less effort for sample preparation compared to tensile testing. Additionally, the i3D features an optical 3D sensor capable of measuring surfaces with high precision, down to a few micrometers. i3D is a compact 2-in-1 solution that elevates your material testing to a new level.

Locally

Locally resolved testing of mechanical properties.

Automated

Fully automated characterization of strength fields.

Fast & Easy

Results within 45 seconds.

Multi Sample

Check multiple samples with, for example, more than 200 measurement points.

2-in-1 Solution: Measurement of Tensile Strength, Yield Strength, and Ductility + Optical 3D Measurements.

Insight into Applications

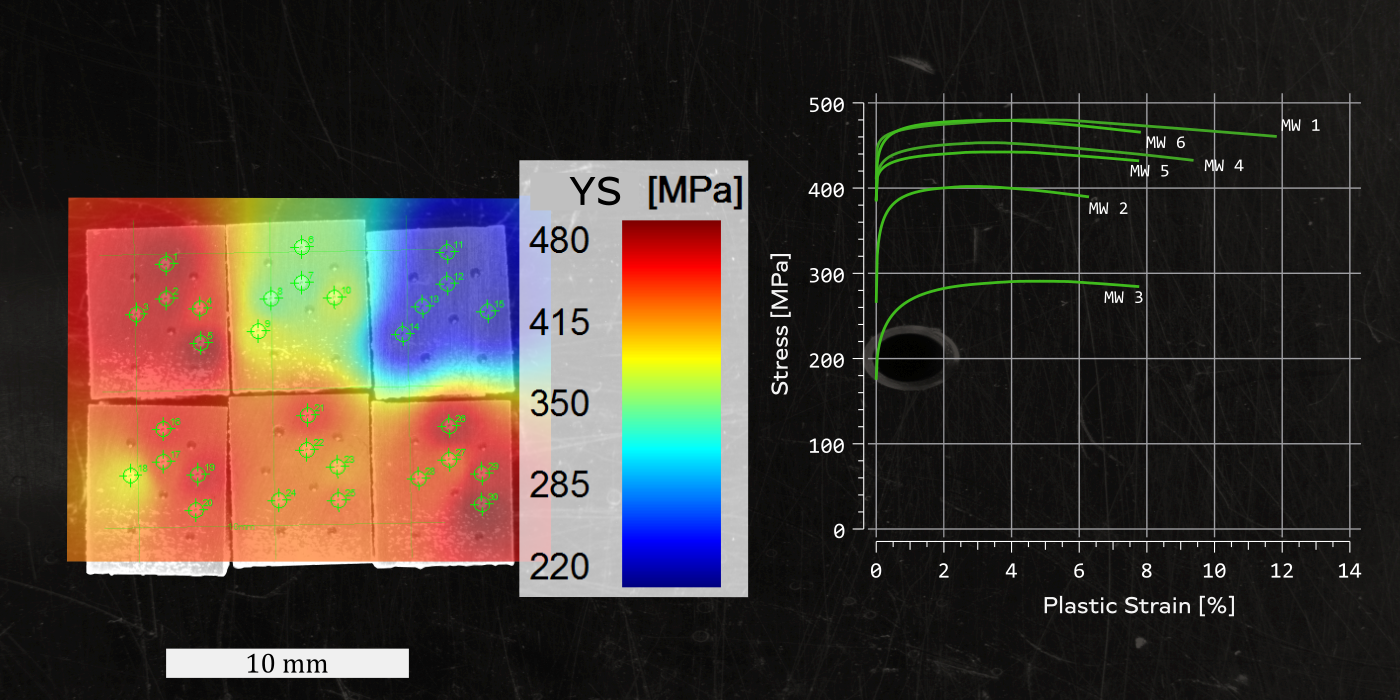

Application #1: Multisample screening for the development of alloys with fast available data.

In the early stages of alloy development, quickly accessible data, including mechanical properties, is often very helpful. It accelerates the process of development through close iteration loops, where steps between adjusting parameters and getting data are accelerated exponentially. Within approx. 30 minutes, 30 plastic flow curves were measured.

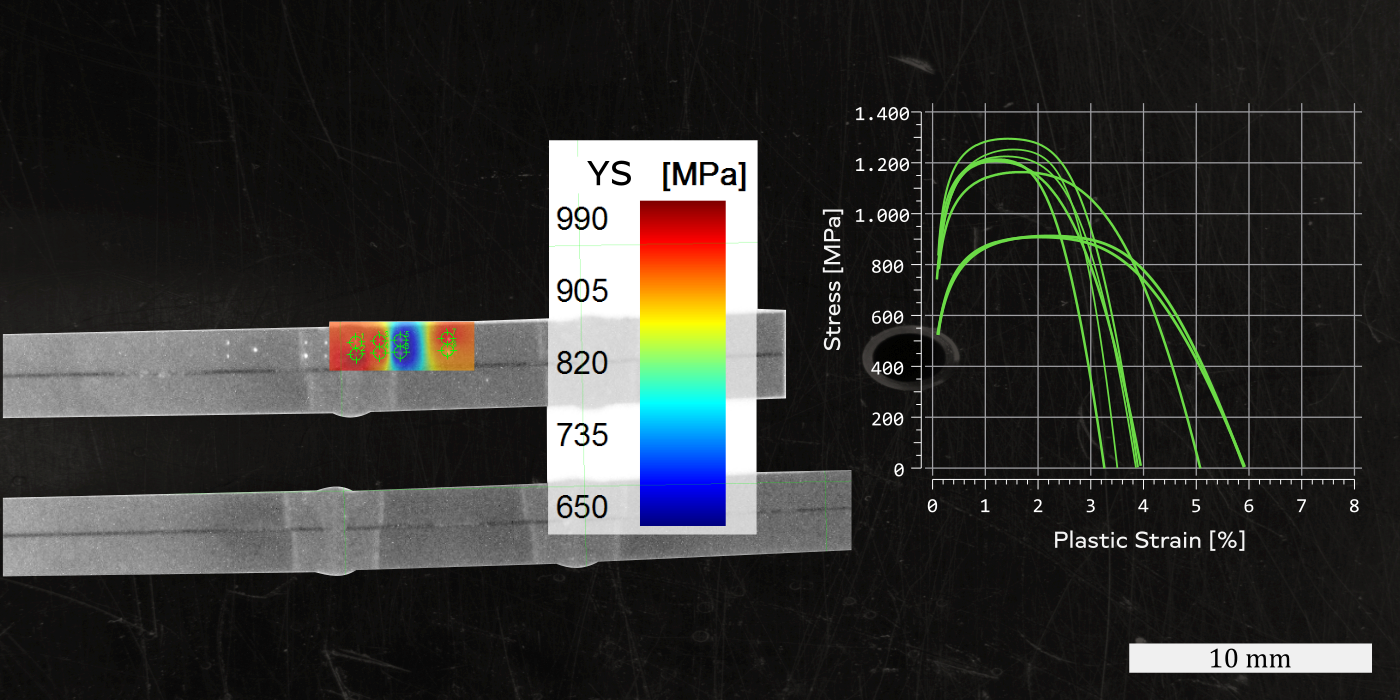

Application #2: Weld seam examination. Testing of tensile strength, yield strength and ductility.

In the context of research work, weld joints were characterized for their mechanical properties in the base material, transition zone, heat-affected zone, and weld seam. Traditionally, the Vickers hardness test was used to measure local hardnesses with measurement points arranged in lines along the weld joint.

Technical Details:

Both variants serve the automated characterization of mechanical properties according to the indentation method specified in DIN SPEC 4864. Additionally, the i3D systems can also be used for optical 3D measurement.

-

ECO: Cost-effective solution optimized for laboratory use.

-

PRO: Additional capability for profile measurements (mapping) and fully automated testing of multiple samples (multisample screening).

| i3D® WLI | Eco | Pro |

|---|---|---|

| Dimensions (L*W*H): | 555 * 381 * 531 mm | 555 * 381 * 531 mm |

| Weight: | 50 kg | 65 kg |

| Test loads (1 kg equals 9.81 N): | 2.5; 5; 10; 30 kg | 2.5; 5; 10; 30 kg |

| Control: | electronically controlled force application | electronically controlled force application |

| System: | integrated computer (Windows) | integrated computer (Windows) |

| Overview function: | - | motorized xy stage & 5MP overview camera |

| Additional hardware: | interferometer | interferometer |

| XY stage travel range: | manual stage | 200 * 88 mm |

| Camera field of view: | 4 x 4 mm | 50 * 50 mm |

| Measurement time: | 60s | optional up to approx. 15s |