Fundamentals of hardness testing - a tool for mechanical material characterization

Hardness testing is basically used as a tool for the mechanical characterization of materials. These include metallic materials (such as steel, aluminum and titanium), plastics, ceramics and mineral materials. For example, a high hardness of a material is often accompanied by a high strength and a higher capacity of resistance to wear. The characteristic feature of hardness testing is the indentation in the material. Depending on the test force and the specific hardness testing method, these indents are approximately a few micrometers to several millimeters in size. Hardness testing is used in a very range in industry. On the one hand, rapid incoming goods inspections or intermediate inspections can be carried out at manufacturing companies, for example in the aerospace, automotive and medical technology sectors. Furthermore, damage analysis and the examination of hardness curves in laboratories are typical. The pointwise testing possibility offers an aid for the microstructure characterization and thus serves the better understanding of the local material properties.Main content:

Definition of hardness

Hardness is the mechanical resistance of a material to material deformation due to the penetration of a harder test specimen.The different hardness testing methods

In hardness testing, individual test methods must be distinguished from one another. Static and dynamic methods and special methods can be defined. In quasi-static methods, the force is applied at a constant and gradually increasing rate. This procedure results in a defined force application time and a holding time. The dynamic hardness testing methods are characterized by an abrupt application of force and are used more frequently in mobile applications. The following hardness testing methods are described in more detail in this text:Brinell hardness testing:

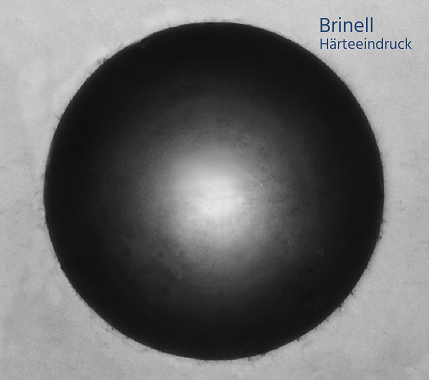

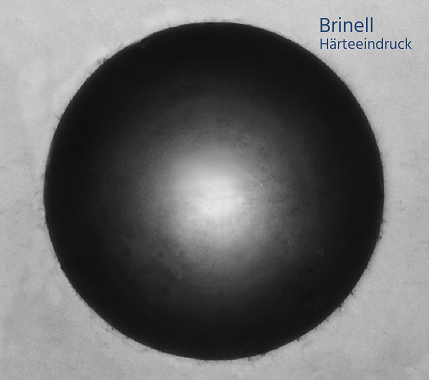

Brinell hardness testing is defined by a hard metal ball pressed vertically onto a prepared specimen surface. Subsequently, two diameters of the remaining indentation lying at right angles to each other are measured optically. The two diameters are used in the following formula for calculating the hardness according to Brinell:

\[HBW = {0,204 * F\over \pi * D ( D - \sqrt{D^2-d^2} ) }\]

Where F is the test load, d is the indentation diameter created in the specimen, D is the ball diameter of the penetrating ball. An exemplary hardness value according to Brinell is written as follows:

\[220 HBW 5/ 250 /30\]

220 HBW is the hardness value determined by carbide ball. The second number describes the ball diameter, and the third number describes the applied test load in kgf. The fourth and last number documents the duration of action of the ball on the specimen. When determining the hardness, this notation should always be used in order to carry out comprehensible measurements and to be able to compare measurement results with each other. Depending on the manufacturer and performance of the testing equipment or software, the indentation diameters are determined automatically via image processing systems and corresponding hardness values are calculated and documented.

The test load to be selected for the Brinell hardness test should always be taken into account the resulting indentation diameter according to the following formula:

\[0,24 D < d < 0,6 D\]

This ensures that the pronounced edge area of the indentation to be measured is not distorted by a bulge due to excessively high test loads or by a blurred or very flat profile due to excessively low test loads. For example, if the test force is too high, a bulge would form, making the indentation appear wider than it actually is. This could lead to the determination of lower hardness values than the actual hardness.

Brinell hardness testers are usually designed to be robust and have long service lives. However, there are some limitations to be mentioned. Brinell testing is not suitable for high-strength materials. Furthermore, due to the larger indentation diameters, the user cannot generate hardness curves with small measuring point distances. Hardness testing according to Vickers is more suitable for this purpose.

Vickers hardness testing:

Vickers hardness testing is defined by a special testing tip. It is a pyramid with a square base and is made of diamond. The opening angle of the Vickers pyramid is 136°. In this method, the testing tip is pressed vertically with a defined force into the specimen surface, held and then pulled out again. The remaining indentation is then measured in its two diagonals. The diagonals run between the opposite corners of the indentation. According to the following formula, this results in the Vickers hardness value:

\[HV = {0,102 * 2F * sin 136°/2 \over \ d^2 } \]

\[=> {0,1891 * F \over \ d^2 } \]

Where d is the length of the diagonal. The notation of Vickers hardness is defined by the following example:

\[500 HV 30 /20 \]

Here, 500 is an exemplary Vickers hardness. 30 is the number describing the test force of 30 kgf or 294 N. The last number describes the exposure time. A great advantage of Vickers hardness testing is the low and applicable test forces down to 0.01 kgf, with which even very small parts, edge areas and layers can be characterized mechanically well.

Rockwell hardness testing:

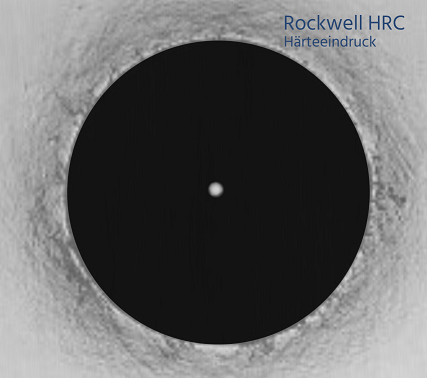

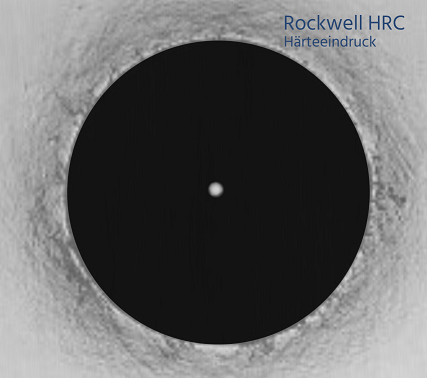

Rockwell hardness testing is subdivided into the Rockwell HRA, HRB, HRC, HR15N and HR30T methods. At this point, the hardness test according to the HRC method will be discussed in more detail. This test also uses a diamond specimen. Its opening angle is 120°, and it has a spherical tip with a radius of 200 µm. The special feature of the Rockwell HRC test is a type of depth measurement. By vertically applying a preload of 98 N (approx. 10kgf), the test tip is leveled in the specimen. Subsequently, the main load of 13773 N acts to return to the preload. The penetration depth of the test probe between the preload and the main load is measured by a displacement transducer. According to the following formula, the hardness is given by Rockwell HRC:

\[HRC = 100 - {h \over \ 0,002 } \]

Here, h describes the penetration depth. The Rockwell test is considered to be a simpler and less expensive type of hardness test than the Vickers or Brinell test. Furthermore, the method can be easily automated for a high test throughput.

Sources:

DIN EN ISO 6506-1, DIN EN ISO 6507-1, DIN EN ISO 6508-1

Order measurements:

#9 Material Testing

Vickers Hardness Test

The Vickers hardness test measures material hardness using a diamond pyramid indenter. It is commonly used in metalworking, tool manufacturing, and materials research, for example, for steel and ceramics.

#10 Material Testing

Brinell Hardness Test

The Brinell hardness test assesses material hardness by pressing a steel ball under a defined pressure. It is commonly used in the metal industry, particularly for cast iron and steel alloys, to determine their strength.

#11 Material Testing

Rockwell Hardness Test

The Rockwell hardness test (HRC) measures the hardness of materials by pressing a conical diamond into the surface. It is commonly used in manufacturing and quality assurance, for example, to quickly determine the hardness of metals and plastics.