Methods of Mechanical Weld Seam Testing

Several methods are used to test the mechanical properties of weld seams. The most common methods include:

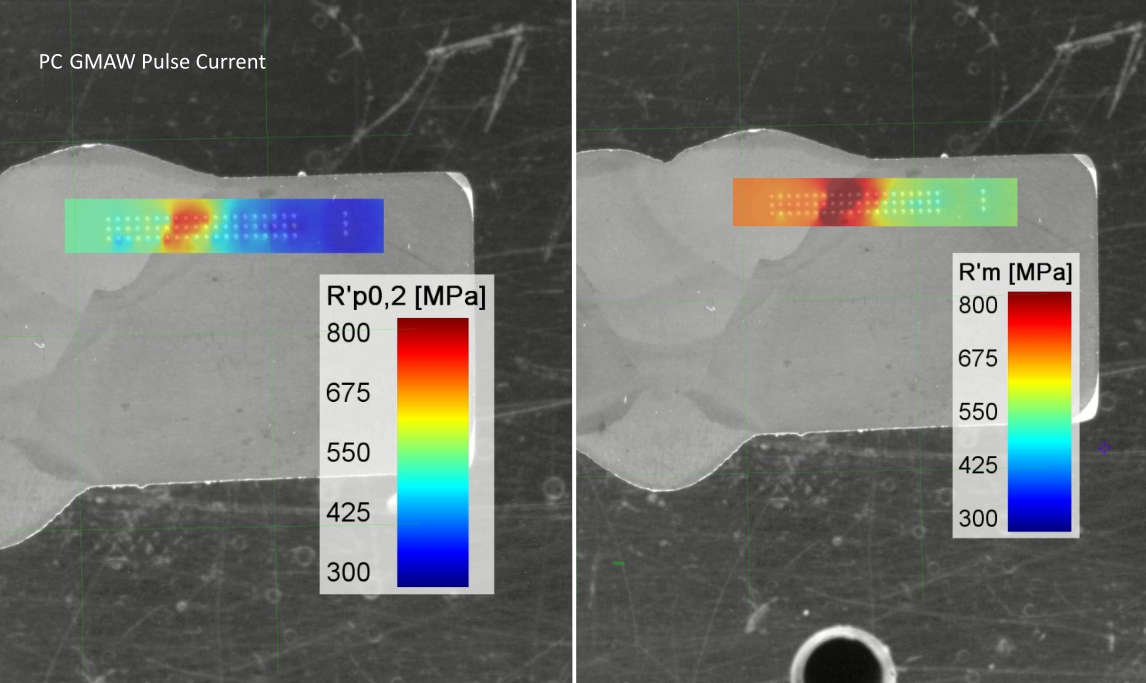

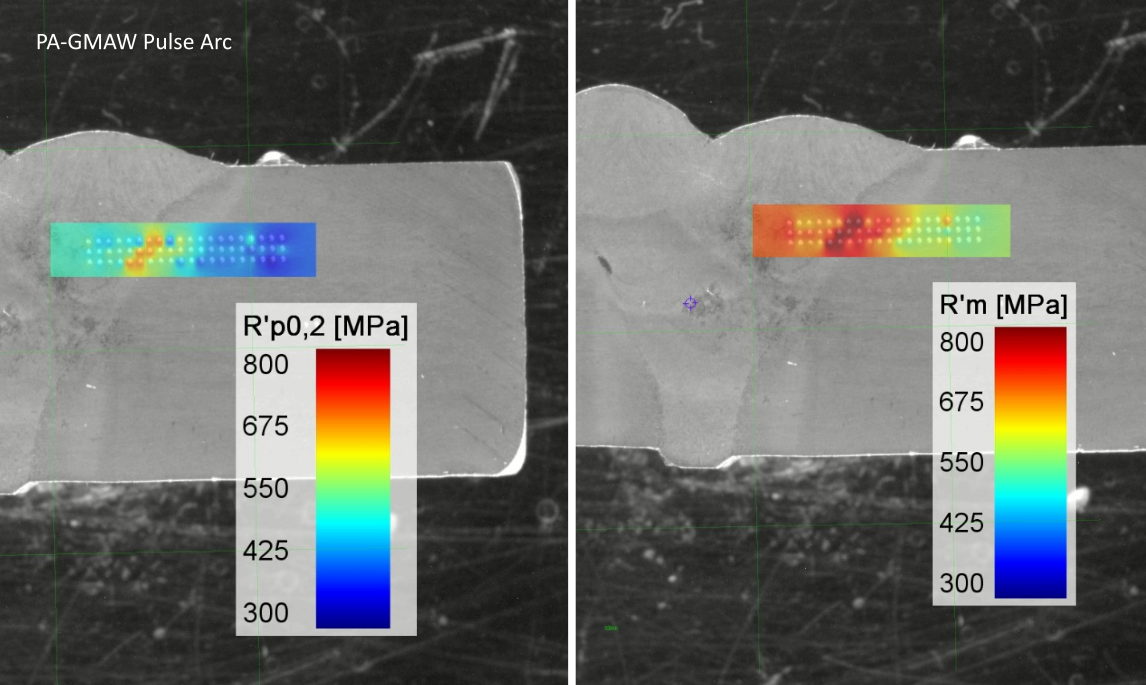

i3D® Imprint Test According to DIN SPEC 4864: This method allows for precise determination of yield strength and tensile strength without fully destroying the sample.

Tensile Tests: The classic method for determining tensile strength and fracture behavior of a weld seam.

Bending Tests: These are used to check the ductility and defect-free nature of weld joints.

Microstructure Analysis: Analyzing the fine-grain structure in TMCP steels to evaluate the effects of thermal influences.

Benefits of Mechanical Weld Seam Testing

Mechanical testing of weld seams offers numerous benefits:

Increased Safety: By accurately determining the mechanical properties, potential weaknesses can be identified early.

Compliance with Standards: Ensures adherence to DIN and ISO standards.

Optimization of Welding Processes: Insights from the tests help improve welding techniques and enhance quality.

Cost Reduction: Preventing material failure reduces rework and downtime costs.

Applications of Mechanical Weld Seam Testing

Mechanical testing methods are used across a wide range of industries:

Construction Industry:

Testing steel beams and other load-bearing structures.Automotive Industry:

Ensuring the strength of body and chassis components.Aerospace:

Testing critical safety components, such as wing joints.Energy Generation:

Quality assurance for weld seams in pressure vessels and pipelines.

Mechanical Weld Seam Testing: Impact on Yield Strength and Tensile Strength of TMCP Steel

Mechanical weld seam testing is an indispensable part of modern quality control. It enables the precise determination of yield strength (YS) and tensile strength (UTS), which are crucial for the load-bearing capacity and safety of weld joints. This is especially important for thermomechanically rolled (TMCP) steels, which are widely used in the construction and engineering industries. Weld seam testing plays a key role in ensuring the integrity and strength of these materials.

Innovations in Weld Seam Testing with Paton Electric Welding Institute of NAS

Our current research explores the impact of modern welding technologies, such as pulsed GMA welding, on the mechanical properties of TMCP steels. These advanced technologies improve welding quality by precisely controlling thermal influences and preserving fine-grain microstructure. The results show that these approaches not only increase yield strength but can also enhance fatigue resistance.

Book your measurements:

#7 Material Testing

Indentation Plastometry Imprint Test

The indentation plastometry based imprint test according to DIN SPEC 4864 enables the precise determination of yield strength, tensile strength, and ductility from indentation tests and serves as an effective alternative to tensile testing. It is used for small parts, welds, and cold working, providing valuable data for finite element analysis (FEM).